WE PROLONG THE LIFE OF YOUR EXTRUDER SCREW BY 6-8 TIMES LONGER THAN OEM

WE ARE THE SCREW AND BARREL REPAIR AND REBUILD EXPERTS

WE CAN REPAIR & RECONDITION ALL TYPES OF SCREWS AND BARRELS

When we receive your screw for rebuilding, our team performs a thorough inspection of the overall condition of your screw which will help us locate and determine the main cause of component failure. Repair and rebuild services include flight repairs, root and radius repairs, and also screw tip repairs. When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company.

With almost 50 years of screw rebuilding experience, we have developed many of the standard screw building and rebuilding processes used in the industry today. Trust the experts in screw rebuilding with your production.

Screw Wear

The performance of a given plasticating unit is defined by the feed screw’s ability to melt and convey the desired rate and quality of polymer to the die or mold. As the screw flights, channel geometry, and surface treatment wear, performance and quality degrades while energy consumption soars. The overall screw design and material(s) processed has a major impact on the wear-life of the plasticating unit, so it is vital to monitor screw wear and performance, regardless of application. Minor wear will have little effect on the overall performance – as machine parameters can be adjusted to maintain productivity. As the radial clearance gap between the screw and barrel increases, energy costs and cycle times rise while rate and quality plummet.

To avoid costly downtime it is important for every company to have a robust maintenance program in place. When screw wear isn’t monitored, the overall wear on the screw can become so severe it is no longer economical to rebuild – leaving you with crippling downtime that can ultimately cost more than the components you attempted to salvage.

Emergency Screw Repair

As an added service, we offer emergency repair. Broken screw? Is emergency repair needed? We are an authorized emergency service repair shop We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed.

Whatever your repair needs are, no matter how big or small, Precision Gear Repair can help.

Things to Consider

- How worn are the screw flights and root

- What are the wear characteristics

- Can the surface treatment be improved

- Cost of Repair vs. Replace

- PGR'S E.M.T.P (Electro Metal Treating Process) To eliminate wear and pro-long wear life by 6-8 times longer versus OEM

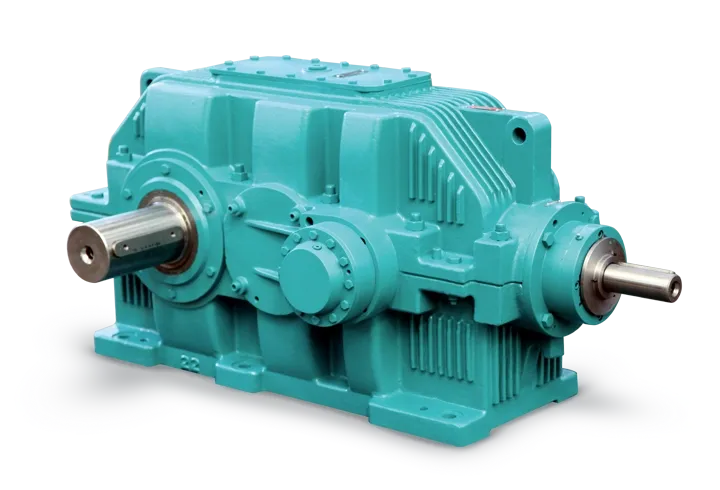

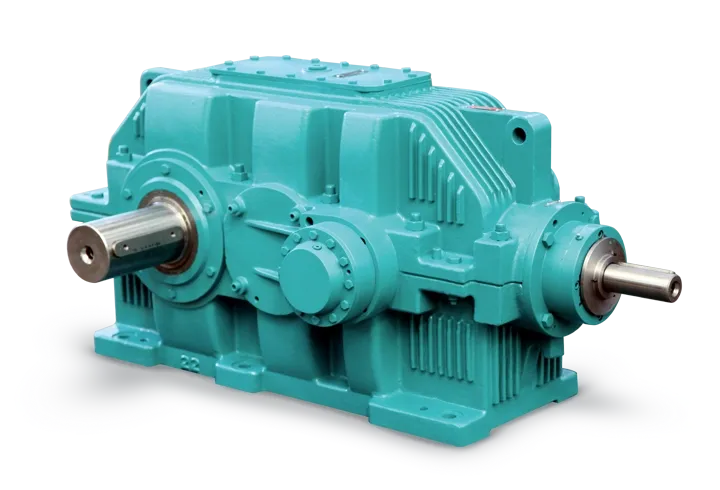

VOTED THE #1 BEST GEARBOX REPAIR COMPANY IN THE USA

WHY CHOOSE PRECISION GEAR REPAIR

We are a 24-hour emergency service repair shop we understand how critical downtime can be that is why our expert technicians will work around the clock to ensure we get your unit back to you in the time frame you need it. When it comes to Screw and Barrel Repair, Precision Gear Repair is are second to none!

Some of the reasons customers choose PGR:

- Unrivaled Quality

- Short Turn-around Times

- 24/7 Emergency Services

- Extensive Gearbox Expertise

- Factory Trained Technicians

- Superior Customer Support

- Reverse Engineer Any Gearbox

- On-Site Engineering & Production

- Personalized Services

Customer Testimonials

Very glad i chose precision gear to do the rebuilding/repairs on our 3 davis standard gearboxes, their state of the art workmenship and lead time was outstanding. After we received the gearboxes back we went ahead and sent out our 15 ft extruder screw to them for repair. And just like the gearboxes the repairs were absolutely perfect and exactly what we needed! I recommend these guys to anybody!

precision gear rebuilt a lufkin T720 gearbox for us. They did an amazing job to say the least, very knowledgable engineers and high quality craftsmanship! We plan on using them again in the future.

PGR rebuilt a falk reducer for me and i am very much satisfied, they were quick and upfront about everything and kept me updated on the status of the gearbox almost everyday. I highly recommend them and i will definitely use them again in the future!

WE CAN REVERSE ENGINEER ANY GEARBOX PART

WE SERVICE VIRTUALLY ALL GEAR & PUMP MANUFACTURERS

Call for a Free Quote on your next rebuild

(832) 935-1692